Posted by Spycor LLC on Dec 30th 2025

When managing a healthcare construction project or upgrading a clinical facility, the stakes for air filtration extend far beyond standard HVAC maintenance. In a hospital environment, air quality is a critical component of infection control and patient safety. For construction firms, general contractors, and facility managers, choosing the right HEPA (High-Efficiency Particulate Air) filter is the first line of defense against Hospital-Acquired Infections (HAIs) and environmental contaminants.

Integrating high-performance HEPA filtration into hospital HVAC systems requires an understanding of MERV ratings, pressure drops, and the specific rigorous demands of healthcare regulatory standards. This guide breaks down the essential factors for selecting HEPA filters that ensure compliance, optimize energy efficiency, and protect both patients and workers during sensitive construction phases.

Understanding the Role of HEPA Filtration

in Healthcare Construction

In the context of healthcare construction—whether it’s a new wing, a renovation, or routine maintenance—dust and debris are more than just a nuisance; they are a liability. Construction activities release Aspergillus and other fungal spores that can be fatal to immunocompromised patients.

A true HEPA filter must be capable of removing at least 99.97% of particles with a size of 0.3 microns. In hospital settings, these filters are utilized in:

-

Positive Pressure Rooms: In environments like Operating Rooms (ORs) and Protective Environment (PE) suites, the goal is to keep the patient—who is often immunocompromised or physically vulnerable—safe from any external pollutants.

-

Negative Pressure Rooms: Conversely, Airborne Infection Isolation Rooms (AIIRs) and ER waiting areas are designed to protect the rest of the hospital from the occupant. These rooms are essential for managing patients with highly contagious respiratory infections (such as Tuberculosis or COVID-19).

-

Portable Air Scrubbers: During active construction and renovation, permanent HVAC systems are often bypassed or sealed to prevent dust from clogging the main ductwork. This is where Portable Air Scrubbers become the most critical tool for a general contractor.

Key Technical Specifications for

Construction Professionals

Selecting the right filter from

1. Filtration Efficiency and Testing

Hospital-grade HEPA filters should be individually tested and certified. Look for filters that meet DOE-STD-3020-2015 or EN 1822 standards. For high-risk areas, a 99.99% efficiency rating is often preferred over the standard 99.97% to provide an extra margin of safety against sub-micron pathogens.

2. High-Capacity vs. Standard Capacity

Construction projects often demand higher airflow to maintain pressure differentials. High-capacity HEPA filters feature more media surface area (often via V-bank designs), which allows for higher CFM (Cubic Feet per Minute) without a massive increase in resistance. This results in a longer filter life and reduced strain on the HVAC blower motors.

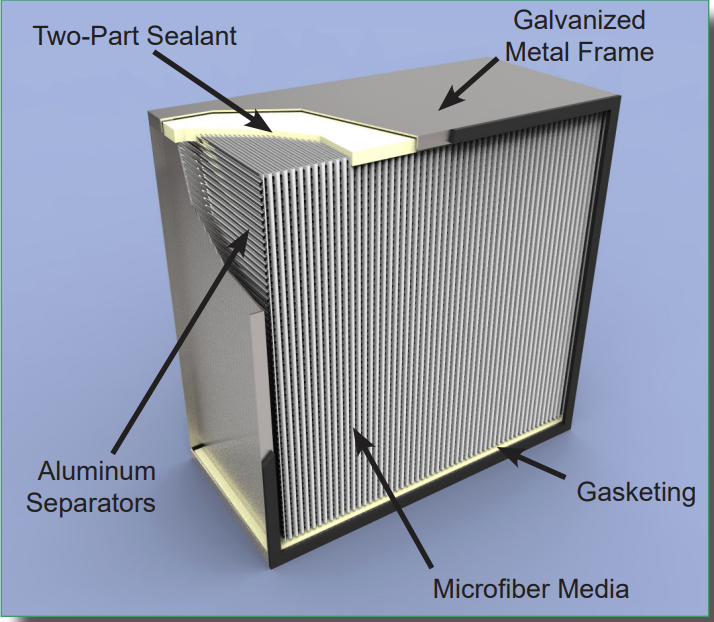

3. Gasket vs. Gel Seals

The seal between the filter and the housing is the most common point of failure.

-

Gasket Seals: Use a neoprene or closed-cell foam to create a physical compression seal.

-

Gel Seals: Utilize a specialized silicone gel channel that creates a leak-proof, airtight connection. In healthcare construction, gel seals are often the gold standard for ceiling-mounted modules to ensure zero bypass.

Optimizing HVAC Performance During

Renovations

One of the biggest challenges for contractors is "Filter Loading." During active construction, HEPA filters can clog rapidly if not protected. To optimize the lifespan of your HEPA units and ensure Google-worthy efficiency in your facility management:

-

Implement Multi-Stage Filtration: Never run a HEPA filter alone. Use MERV 8 or MERV 11 pre-filters to capture large construction dust. This ensures the expensive HEPA media is reserved for the microscopic particles it was designed for.

-

Monitor Pressure Drop: Utilize manometers or Magnehelic gauges to track the pressure differential across the filter bank. A sudden spike indicates a breach or heavy loading, while a drop could indicate a tear in the media.

Compliance and Regulatory Standards

To ensure your facility remains compliant with ASHRAE 170 (Ventilation of Health Care Facilities) and CDC guidelines, your HEPA selection must be precise. Construction firms must also adhere to ICRA (Infection Control Risk Assessment) protocols. Using high-quality filters from trusted suppliers like Spycor ensures that your project meets the rigorous documentation requirements during safety inspections.

Why Quality HEPA Media Matters

Not all HEPA filters are created equal. Cheap alternatives often use inferior glass fiber media that can "shed" or develop pinhole leaks under high-velocity air. Professional-grade HEPA filters available at Spycor utilize moisture-resistant, micro-glass fiber media designed to withstand the humidity fluctuations often found in large-scale hospital HVAC systems.

Selecting the Right Size and Configuration

Standard hospital HVAC systems typically use 24x24x11.5 inch filters, but renovations often require specialized sizes for portable scrubbers or ceiling diffusers. Before ordering, verify:

-

Actual vs. Nominal Size: Ensure the filter fits the existing housing or the specific air scrubber model (e.g., Abatement Technologies or OmniAire).

-

Frame Material: Aluminum frames are preferred in healthcare for their corrosion resistance and lightweight nature compared to galvanized steel.

Step Up Your Infection Control Today

Protecting your job site and your patients starts with elite air filtration. Don't compromise on air quality.

Reliable Air Filtration is Just a Click Away. For bulk orders, technical specifications, and the best selection of healthcare-grade filtration products, contact us!

Frequently Asked Questions (FAQ)

How often should HEPA filters be changed in a hospital construction zone?

In an active construction environment, HEPA filters should be monitored daily via pressure gauges. Generally, if used with proper pre-filtration, a HEPA filter can last 6 to 12 months. However, in heavy dust conditions, they may need replacement sooner to maintain required CFM levels.

What is the difference between HEPA and ULPA filters?

HEPA filters capture 99.97% of particles at 0.3 microns. ULPA (Ultra-Low Particulate Air) filters capture 99.999% of particles at 0.12 microns. While ULPA offers higher efficiency, they also create significantly higher resistance to airflow, which can damage standard hospital HVAC motors if not specifically designed for them.

Can I vacuum or clean a HEPA filter to reuse it?

No. HEPA filters are "deep-loading" filters. Attempting to clean them with a vacuum or compressed air will damage the delicate micro-glass fibers and create leaks, rendering the filter useless for infection control. Always replace loaded filters with new, certified units.

What MERV rating is equivalent to HEPA?

HEPA filters do not fit on the standard MERV scale, but if they did, they would be considered MERV 17 through 20. For healthcare facilities, ASHRAE recommends at least MERV 14 for general areas, but HEPA is required for critical environments like ORs and AIIRs.

Why is 0.3 microns the standard for testing?

The 0.3-micron size is known as the "Most Penetrating Particle Size" (MPPS). Particles both larger and smaller than 0.3 microns are actually easier to catch due to physical principles like interception and Brownian motion. If a filter can catch a 0.3-micron particle, it is even more effective at catching smaller viruses and larger bacteria.

How do I ensure my HEPA filter is properly installed?

Always perform a "DOP" or "PAO" leak test after installation. This involves introducing a known concentration of aerosolized smoke upstream and using a photometer downstream to ensure no leaks are present around the frame or through the media.