Posted by Spycor Building on Jan 16th 2026

High-performance building envelopes require more than just a standard house wrap; they demand a sophisticated air and water resistive barrier (WRB) that can withstand the rigors of the job site while ensuring long-term structural integrity. For commercial contractors and custom home builders, DELTA®-VENT SA has emerged as the industry benchmark for vapor-permeable, self-adhered membranes.

Managing air leakage and moisture migration is the single most important factor in preventing rot, mold, and premature building failure. As energy codes become more stringent, the transition from mechanically fastened wraps to self-adhered barriers like DELTA®-VENT SA is no longer an option—it is a necessity for professional-grade construction.

What is DELTA®-VENT SA?

DELTA®-VENT SA is a high-performance, vapor-permeable, self-adhered air and water-resistive barrier. Unlike traditional wraps that require thousands of staples or nails (each creating a potential leak point), this membrane utilizes a full-surface adhesive backing to create a continuous, airtight bond with the substrate.

Constructed from a high-strength spun-bonded polypropylene fabric, it is laminated to a specialized water-resistive layer. This combination allows the building to "breathe" by letting moisture vapor escape from the wall cavity while remaining completely airtight and watertight from the exterior.

Why Contractors are Switching to DELTA-

VENT SA for Commercial Projects

1. Eliminating Air Leakage

Air leakage can account for up to 40% of a building's energy loss. Traditional mechanically attached barriers often "billow" or "pump" air when wind hits the facade. Because DELTA®-VENT SA is fully bonded to the sheathing, it eliminates air movement behind the membrane, significantly increasing the thermal efficiency of the insulation and the building's overall R-value.

2. Superior Vapor Permeability

With a high vapor permeance rating, DELTA®-VENT SA ensures that any incidental moisture trapped inside the wall cavity during construction or through interior humidity can migrate to the outside. This prevents the "sandwich effect" where moisture is trapped between two impermeable layers, which is the leading cause of structural decay in modern tight-built homes.

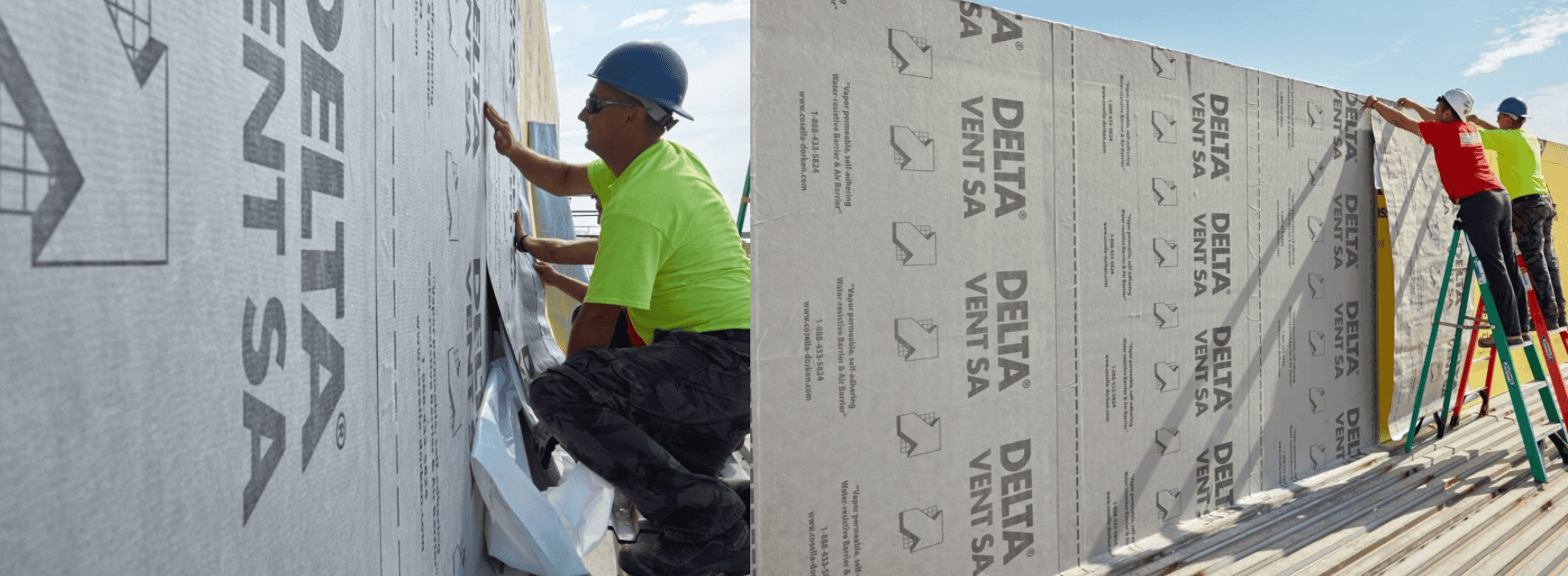

3. Simplified Installation and Labor Savings

For contractors, time is money. DELTA®-VENT SA features a split-release liner, making it manageable for small crews to install accurately. The self-adhering nature eliminates the need for separate seam tapes in many areas and removes the requirement for "cap nails" that can tear during high winds.

4. Robust Weather Resistance

Commercial job sites often experience delays. DELTA®-VENT SA is highly UV resistant, allowing it to remain exposed to the elements for extended periods without degrading. Its rugged outer layer is designed to withstand the scrapes and bumps of a busy construction site.

Technical Specifications for Builders

When specifying an air barrier for a commercial project, the technical data tells the story. DELTA®-VENT SA meets and exceeds the most stringent North American building codes:

- Vapor Permeance: High permeability allows for rapid drying of the wall assembly. With an industry-leading 50 perms (per ASTM E96), DELTA-VENT SA enables moisture vapor to diffuse outward efficiently, preventing interstitial condensation and mold growth even in humid or mixed climates.

- Air Leakage: Far exceeds the requirements of the Air Barrier Association of America (ABAA). Independent testing to ASTM E2357 shows air permeance as low as 0.002 L/s·m² at 75 Pa—dramatically surpassing ABAA's most stringent thresholds and achieving airtight assemblies without fastener penetrations.

- Adhesion: Aggressive tack allows for application on various substrates, including OSB, plywood, masonry, and exterior-grade gypsum sheathing. The full-surface high-tack adhesive provides reliable, long-term bonding that eliminates the need for mechanical fasteners, reducing potential leak points and installation time.

- Temperature Stability: Engineered to perform in extreme cold and high-heat environments without losing adhesion. The membrane maintains its aggressive tack and dimensional stability during application and service in a wide range of job-site conditions, from sub-freezing winters to intense summer heat.

Proper Substrate Preparation: A

Contractor’s Guide

To ensure the 1st-page-worthy performance of DELTA®-VENT SA on your project, substrate preparation is key.

- Cleanliness: The surface must be dry and free of dust, oils, or frost. While the adhesive is aggressive, debris will compromise the bond. Proper substrate preparation—such as brushing or blowing off loose particles and ensuring moisture content is below 15%—creates the foundation for a permanent, high-tack seal that withstands long-term building movement and environmental stress.

- Priming: In many applications, especially on dusty masonry or in cold weather, using a primer (such as DELTA®-HF PRIMER) is recommended to ensure a permanent bond. DELTA-HF PRIMER, a solvent-free acrylic formula, applies quickly with a roller, dries to a tacky state in 20–60 minutes (depending on temperature and humidity), and dramatically improves adhesion on porous or challenging substrates like concrete block, aged OSB, or exterior gypsum.

- Pressure is Essential: Use a hand roller after application. The adhesive is pressure-sensitive; rolling the membrane ensures that the chemical bond is fully engaged with the substrate. Firm, systematic rolling from the center outward eliminates air pockets, activates the full-surface aggressive tack, and creates intimate contact that maximizes long-term durability against wind loads and thermal cycling.

- Lapping: Maintain the manufacturer-recommended overlaps (usually 4 inches) to ensure a continuous water-shedding surface. Vertical side laps should be at least 4 inches, while horizontal end laps are typically 6 inches for optimal water shedding and airtightness; the exclusive self-adhering edge laps bond seamlessly without additional tape in most cases.

Cost-Benefit Analysis for Home Builders

While the upfront material cost of a self-adhered barrier is higher than a perforated wrap, the total cost of ownership tells a different story:

- Reduced Callbacks: By eliminating leaks and mold risks, builders save thousands in potential litigation and repairs. DELTA-VENT SA's fully self-adhered design with no fasteners prevents penetration points that commonly cause water intrusion and air leaks in traditional systems, drastically cutting post-occupancy issues like moisture damage or mold growth.

- Blower Door Success: Ensuring a pass on the first blower door test avoids costly remediation and scheduling delays. With air permeance as low as 0.002 L/s·m² at 75 Pa (far exceeding ASTM E2357 and ABAA standards), DELTA-VENT SA delivers airtight assemblies that routinely achieve tighter results—often improving blower door scores by 20-30% compared to mechanically fastened alternatives.

- Marketing Advantage: Builders can market their homes as "High-Performance" or "Net-Zero Ready," commanding a premium price in the market. Specifying DELTA-VENT SA supports superior energy efficiency, healthier indoor air quality, and compliance with green certifications (e.g., Red List Compliant, DECLARE label), allowing firms to differentiate projects as durable, low-energy buildings that appeal to eco-conscious clients.

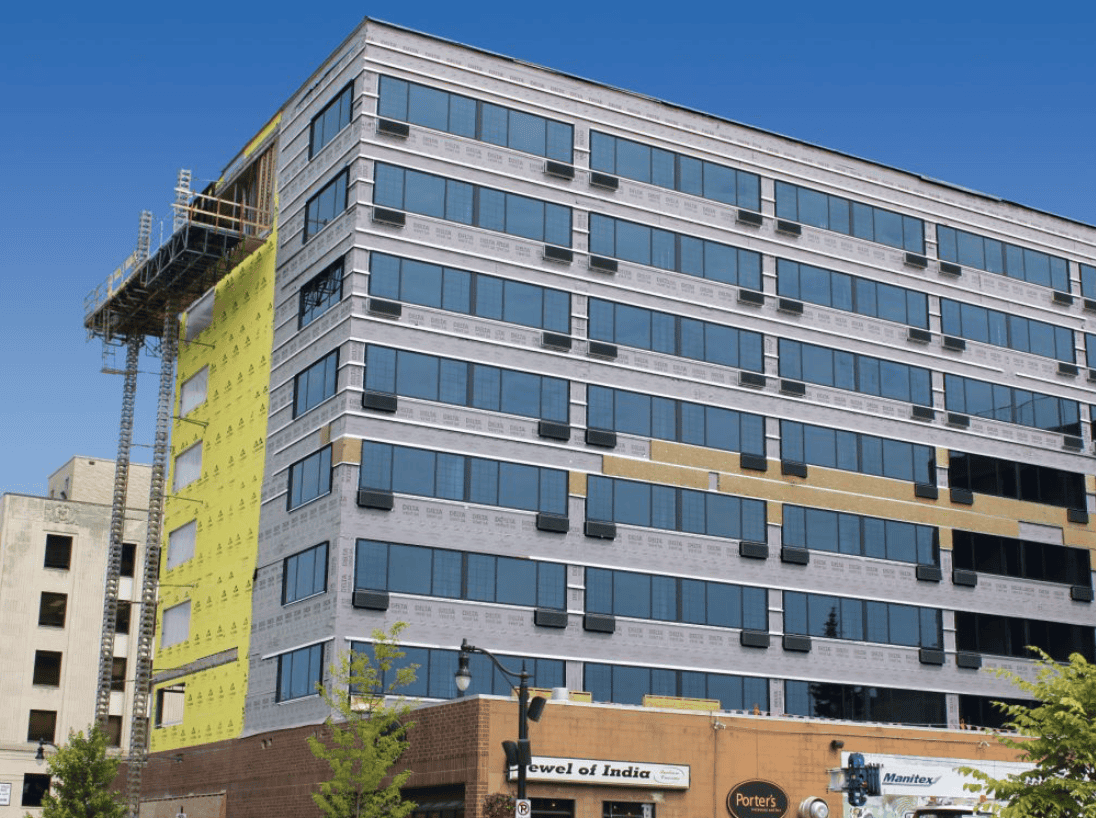

DELTA®-VENT SA in Specialized Wall

Assemblies

Whether you are building a rainscreen system, a metal panel facade, or a traditional brick veneer, DELTA®-VENT SA provides the necessary versatility. It is particularly effective behind open-joint cladding systems where the barrier might be partially visible, as its matte finish and durability provide a professional aesthetic and functional security.

Why Buy from Spycor Building Products?

At Spycor Building Products, we specialize in the moisture management systems that protect your reputation. When you order DELTA®-VENT SA from us, you are getting a product that has been vetted by building science experts for its performance in the toughest North American climates.

Ready to Ship – Protect your building with the best in the industry.

Order DELTA®-VENT SA Now at spycorbuilding.com

Frequently Asked Questions (FAQ)

Does DELTA®-VENT SA require a primer?

While it has an incredibly aggressive adhesive, a primer is often recommended for OSB, concrete, or masonry surfaces, especially when installing in temperatures below 40°F (4°C). Always check the specific job site conditions.

Can it be used as a roof underlayment?

No, DELTA®-VENT SA is specifically engineered for vertical wall applications. For high-performance roofing needs, look for DELTA®-Roofing products.

How long can DELTA®-VENT SA be exposed to UV?

It is designed to withstand UV exposure for up to 120 days, providing ample time for the installation of the final exterior cladding without compromising the integrity of the barrier.

Is it compatible with sealants?

It is compatible with most professional-grade sealants. However, it is highly recommended to use DELTA®-specific accessories like DELTA®-TILXX or DELTA®-FLEXX-BAND for detailing to ensure a warrantied system.

What is the difference between DELTA®-VENT SA and DELTA®-VENT S?

The "SA" stands for Self-Adhered. DELTA®-VENT S is a mechanically fastened version of the same high-quality membrane. The SA version provides a superior air seal because it is fully bonded to the substrate.

Can I install this over damp sheathing?

No. For the adhesive to bond properly, the substrate must be dry to the touch. Installing over wet materials can trap moisture and prevent the adhesive from reaching its full design strength.