Posted by Spycor LLC on Sep 10th 2025

Construction sites are dynamic environments, filled with activity that can stir up massive amounts of dust, debris, and other airborne particles. While visible dust is a nuisance, the invisible dangers—such as mold spores, asbestos fibers, and lead dust—pose serious health risks to workers and occupants. Simply opening a window isn't enough to protect against these hazards. This is where a negative air machine becomes an indispensable tool. It's not just another piece of equipment; it's a critical part of your safety and compliance strategy, ensuring that contaminated air stays contained and clean air is prioritized. This guide will walk you through what these machines are, why they are essential for your projects, and what to look for when choosing the right one for your job site.

What is a Negative Air Machine?

A negative air machine is a powerful air filtration device that uses a fan and a series of filters to create a controlled pressure environment. By pulling air out of a sealed workspace and exhausting it (often outside), it creates a slight vacuum, or "negative pressure." This ensures that air—and any dangerous particles it contains—is constantly flowing into the containment area, preventing it from escaping and contaminating other parts of the building. The air is then passed through a high-efficiency particulate air (HEPA) filter, which captures 99.97% of particles as small as 0.3 microns, including harmful mold spores and asbestos fibers.

Why Negative Air Machines Are Essential

on Construction Sites

Controlling airborne contaminants is a matter of safety, regulatory compliance, and professionalism. Here are the most critical use cases where a negative air machine is a must-have:

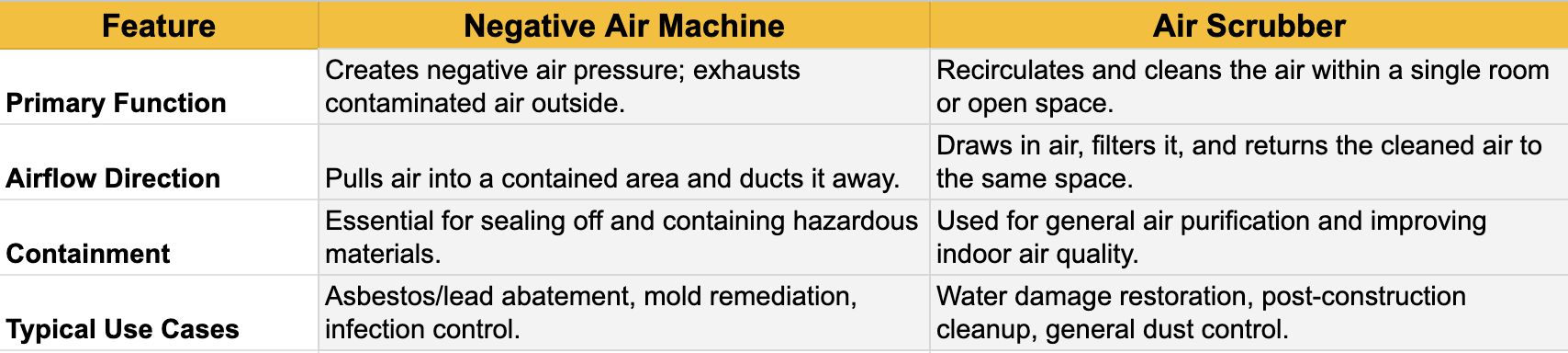

- Asbestos and Lead Abatement: During the removal of hazardous materials like asbestos and lead paint, a negative air machine is non-negotiable. It creates an airtight zone that prevents microscopic fibers and dust from spreading, protecting both workers and the surrounding environment from exposure.

- Mold Remediation: When tackling mold, a negative air machine prevents spores from becoming airborne and spreading to clean areas. It contains the spores within the remediation zone, allowing for safe and effective removal.

- Dust Control During Demolition and Remodeling: From cutting drywall to sanding wood, construction tasks generate huge amounts of dust. A negative air machine continuously filters the air, reducing cleanup time and protecting HVAC systems, sensitive equipment, and nearby occupants from dust contamination.

- Infection Control (ICRA) in Healthcare Facilities: When renovating a hospital, clinic, or other medical setting, a negative air machine is a key component of Infection Control Risk Assessment (ICRA) protocols. It creates isolation zones to prevent the spread of pathogens and airborne microbes to patients and staff.

Negative Air Machine vs. Air Scrubber:

What's the Difference?

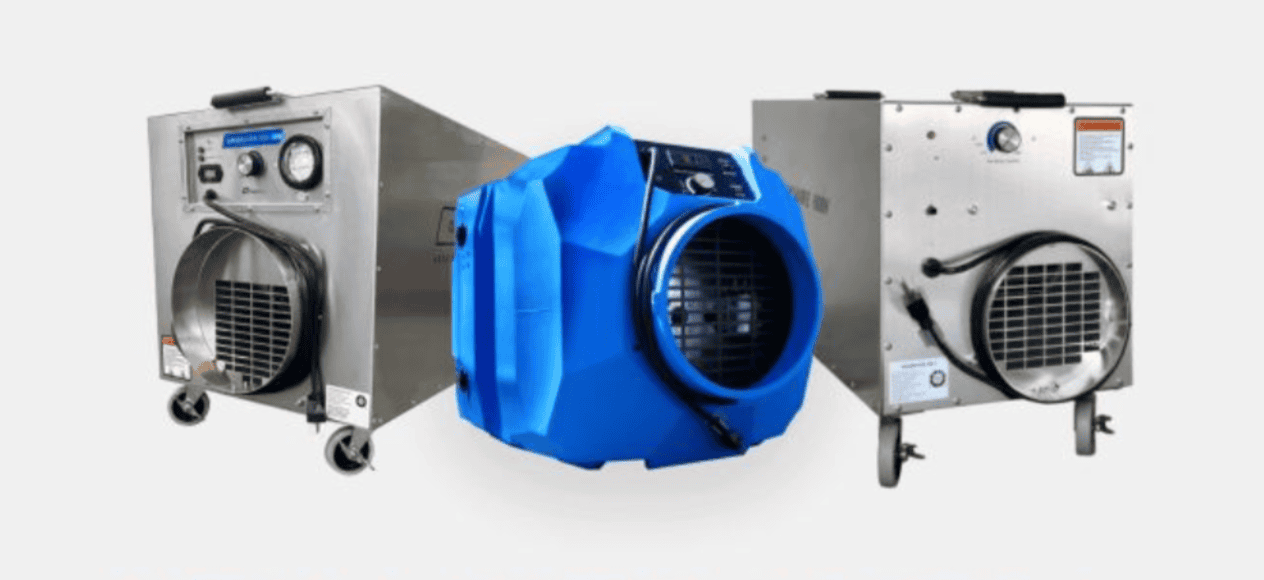

While the terms are often used interchangeably, they serve different functions. Understanding the distinction is key to choosing the right tool for the job.

How to Choose the Right Negative Air

Machine for Your Project

Selecting the right machine ensures effective containment and maximizes your investment. Here are the key factors to consider:

- Cubic Feet per Minute (CFM): This is the measure of how much air a machine can process per minute. You need to calculate the CFM required for your specific space to ensure proper air changes per hour (ACH). A higher CFM is better for larger spaces or more heavily contaminated areas.

- HEPA Filtration: Ensure the machine is equipped with a certified HEPA filter. This is the gold standard for trapping the smallest, most dangerous particles.

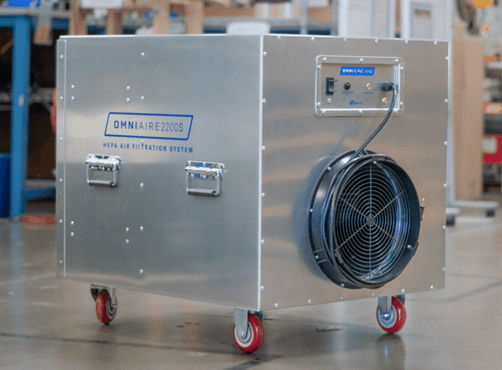

- Portability & Durability: Look for a machine that is easy to move and built to withstand the rugged conditions of a job site. Features like non-marking casters and a durable, sealed housing are crucial.

- Variable Speed Control: A machine with variable speed control gives you flexibility to adjust airflow for different project sizes, from a small room to a large containment area.

Ready to Create a Safer Job

Site?

Don't compromise on air quality. A negative air machine is an investment in the health of your crew, the safety of your clients, and the success of your business. Our selection of professional-grade negative air machines are built for the toughest jobs, with powerful HEPA filtration and rugged designs.

Explore Our Top Negative Air Machines for Construction at Spycor.com

Frequently Asked Questions (FAQs)

How do you calculate the CFM needed for a room?

To calculate the required CFM, use this simple formula: CFM = (Room Volume in Cubic Feet x Air Changes per Hour) / 60 The required ACH varies by project type, but a common standard for construction is 4 to 6 air changes per hour.

Can I use a negative air machine as an air scrubber?

Yes. Many negative air machines can be used as air scrubbers by simply running them without ducting, allowing them to recirculate and clean the air within the space.

How often should I change the filters?

The pre-filter should be checked and changed frequently, often daily, as it captures the majority of large debris. The HEPA filter has a longer lifespan but should be checked regularly and replaced when the filter change indicator light comes on or when you notice a drop in performance.

Are negative air machines loud?

The noise level varies by model. Look for machines with a low decibel rating, especially if you will be working in occupied spaces or for long hours.

What certifications should I look for?

Look for machines with UL listed components and those that are tested for HEPA performance. This ensures the unit meets strict safety and efficiency standards.