Posted by Spycor LLC on Jan 22nd 2026

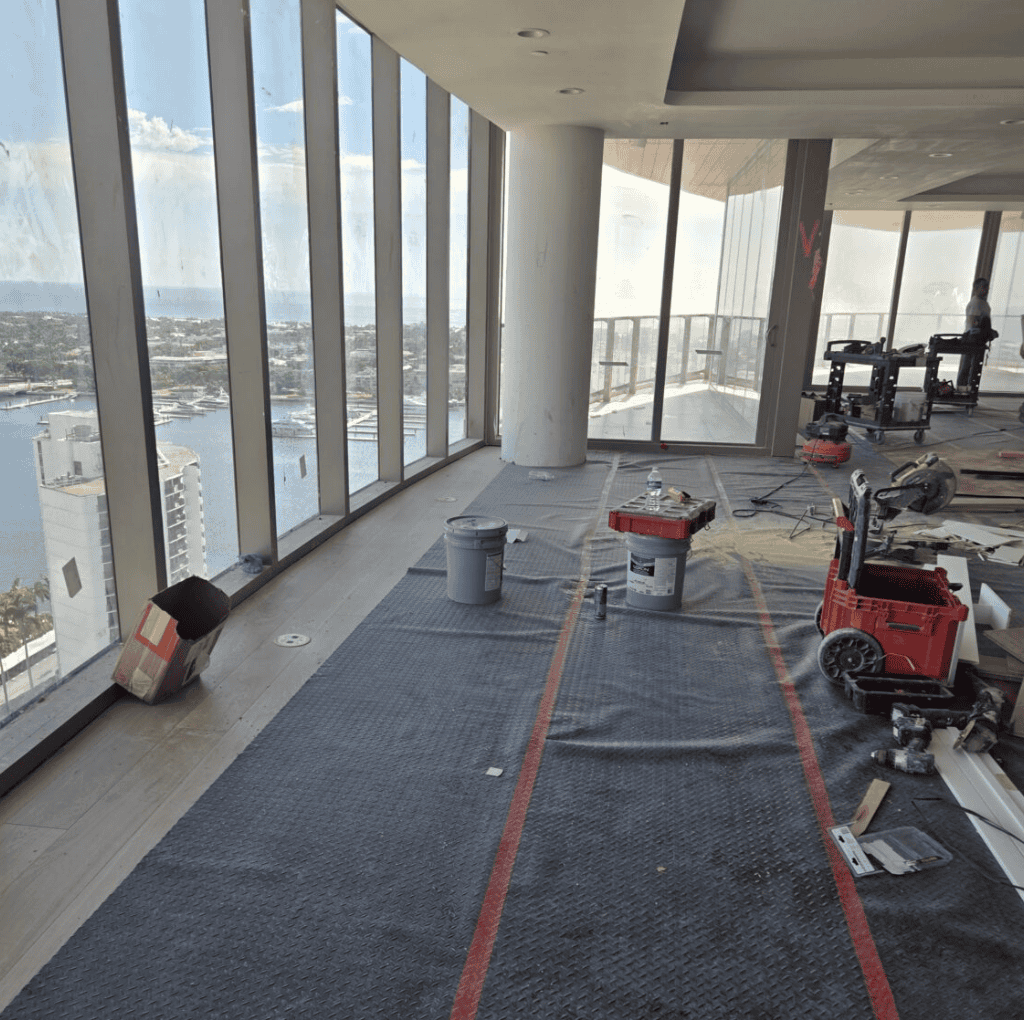

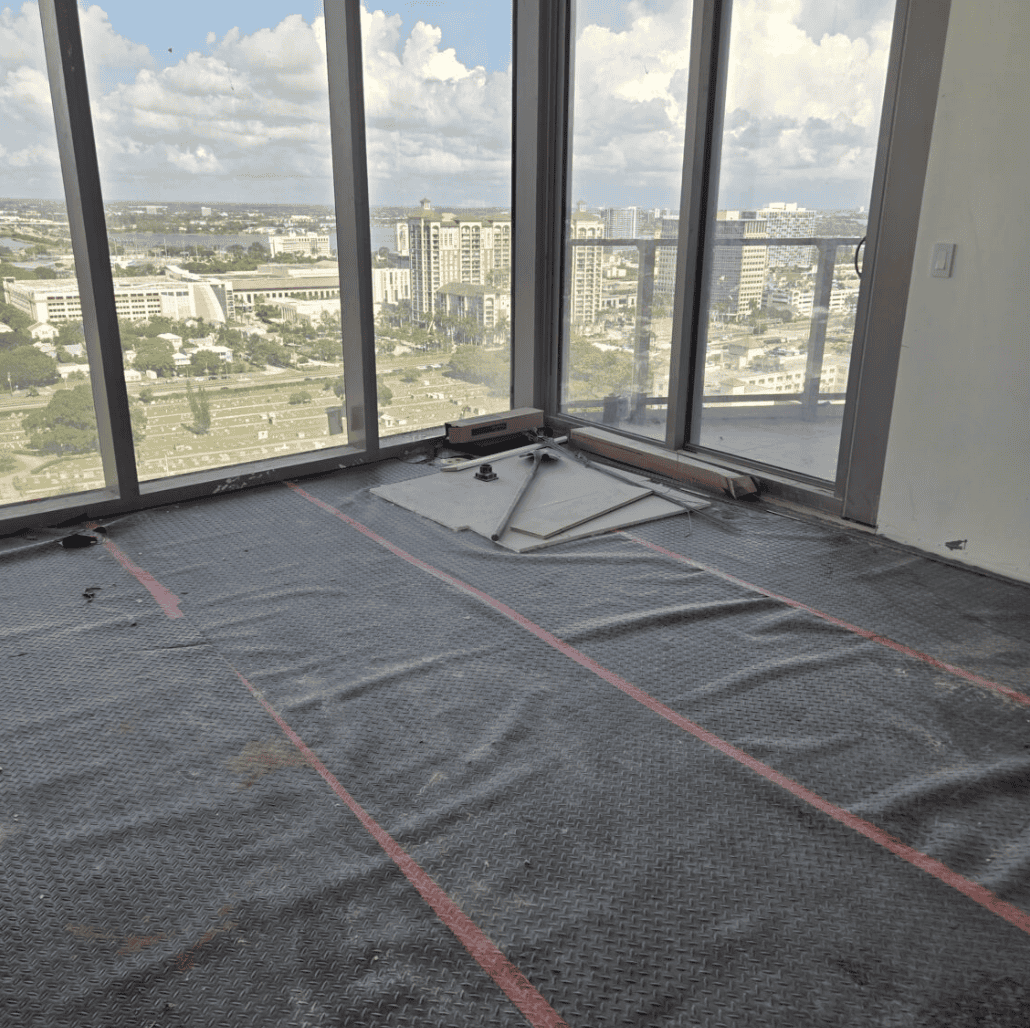

Maintaining the integrity of finished surfaces is a critical requirement in commercial construction management. On high-traffic jobsites, standard protection methods often fail to provide the mechanical resistance necessary to prevent costly damage claims. When project specifications do not mandate fire-rated materials, Cover Guard® Non-Flame Retardant (Non-FR) protective material provides the most durable and cost-effective solution for safeguarding expensive substrates.

Engineered from high-density polyethylene (HDPE), this black diamond-plate material is designed specifically for contractors who require a high-performance barrier against impact, heavy foot traffic, and equipment movement without the added cost of flame-retardant additives.

Engineering Performance: The Cover

Guard® Non-FR Advantage

Cover Guard® is not a temporary film; it is a high-performance floor system designed for the rigors of industrial and commercial environments.

Superior Impact Resistance

Unlike cardboard or thin plastic sheeting, Cover Guard’s HDPE composition absorbs the energy of dropped tools and heavy machinery. This prevents gouges in polished concrete, stone, and hardwood that thinner alternatives simply cannot stop.

Integrated Safety with Diamond Plate Traction

Site safety is paramount. The diamond plate floor protection roll features a raised-texture surface that significantly improves slip resistance. This ensures a stable walking surface for crews and better grip for wheeled equipment, even in dusty or damp conditions.

100% Moisture and Chemical Barrier

Spills are inevitable on a commercial site. Because Cover Guard® is non-porous, it acts as a total liquid barrier. It protects against water, oils, and construction chemicals, ensuring that no contaminants reach the finished floor during the build-out phase.

Strategic Cost Management: Why Choose Non-FR?

In commercial bidding, every line item matters. Non-flame retardant surface protection offers the exact same physical durability as its Flame Retardant (FR) counterpart but at a lower price point.

-

When to use Black (Non-FR): Ideal for standard commercial renovations, warehouse builds, and residential projects where fire-code certifications like NFPA 701 are not mandated.

-

Sustainability: Because of its high-strength HDPE construction, Cover Guard® is reusable. Contractors can sweep, roll, and relocate the material from one project phase to the next, significantly reducing the total cost per square foot over the project lifecycle.

Installation Protocol for Maximum Surface

Safety

To ensure the highest level of protection, professional installation should follow these technical guidelines:

-

Substrate Preparation: Ensure the floor is completely free of debris to prevent "sandpapering" under the weight of traffic.

-

Seam Management: Overlap seams by a minimum of 2 inches.

-

Securement: Use high-adhesion PE tape on all seams. For perimeter securement, ensure the tape used is compatible with the finished floor to avoid adhesive transfer.

-

Full Coverage: Cut material to fit tightly around pillars, door frames, and corners using a standard utility knife for a professional finish.

Eliminate costly surface repairs before they occur in commercial construction, the cost of a single scratch on a finished substrate often exceeds the cost of premium protection for the entire site.

Shop Cover Guard® Non-FR Black Rolls Now at Spycor.com

Frequently Asked Questions (FAQ)

Is Black Cover Guard® Non-FR suitable for all flooring types?

Yes. It is chemically inert and non-staining, making it safe for marble, granite, LVT, hardwood, and polished concrete. Ensure the floor is fully cured before application.

Can I use the Non-FR version for outdoor staging?

Absolutely. The HDPE material is waterproof and UV-resistant, making it excellent for outdoor walkways or staging equipment on sensitive exterior surfaces.

How does Cover Guard® compare to Masonite?

Cover Guard® is easier to install, waterproof, and more compact to store. Unlike Masonite, it will not absorb moisture or rot, and the diamond-plate surface provides significantly better slip resistance.

Is this product recyclable?

Yes. Cover Guard® is 100% recyclable, assisting projects in meeting LEED and other sustainability requirements.

What is the best way to clean the material for reuse?

Simply sweep or vacuum debris. For spills, the material can be mopped with standard water and mild detergent without compromising its structural integrity.