Posted by Spycor LLC on Oct 9th 2025

Unprotected floors turn minor mishaps into major setbacks. Spills, heavy equipment, and foot traffic can scar concrete slabs, hardwood subfloors, or tile installations, inflating repair costs by thousands. Strategic construction floor protection isn’t an afterthought—it’s a proactive shield that extends material life, streamlines workflows, and ensures project budgets stay on track. By prioritizing construction floor protection, contractors can prevent costly delays, maintain professional standards, and deliver flawless results that impress clients. This critical step transforms potential liabilities into opportunities for efficiency, ensuring every project—from residential remodels to large-scale commercial builds—stays on schedule and within budget while protecting valuable surfaces.

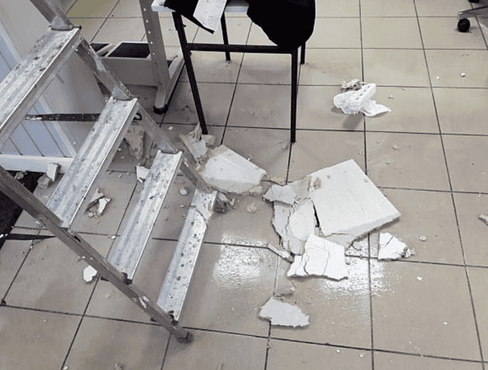

The Hidden Costs of Skipping Construction Floor Protection

Contractors know the drill: a single dropped tool or adhesive spill on an exposed surface means downtime for cleanup and fixes. Studies from the Construction Industry Institute highlight that surface damage accounts for up to 15% of project overruns. Reusable construction floor protection flips this script by creating a durable barrier against abrasions, chemicals, and moisture—without the waste of single-use sheets. Opting for reusable options cuts material expenses by 40-60% over disposable alternatives, per industry benchmarks, while reducing landfill contributions.

Why Reusable Beats Temporary Every Time

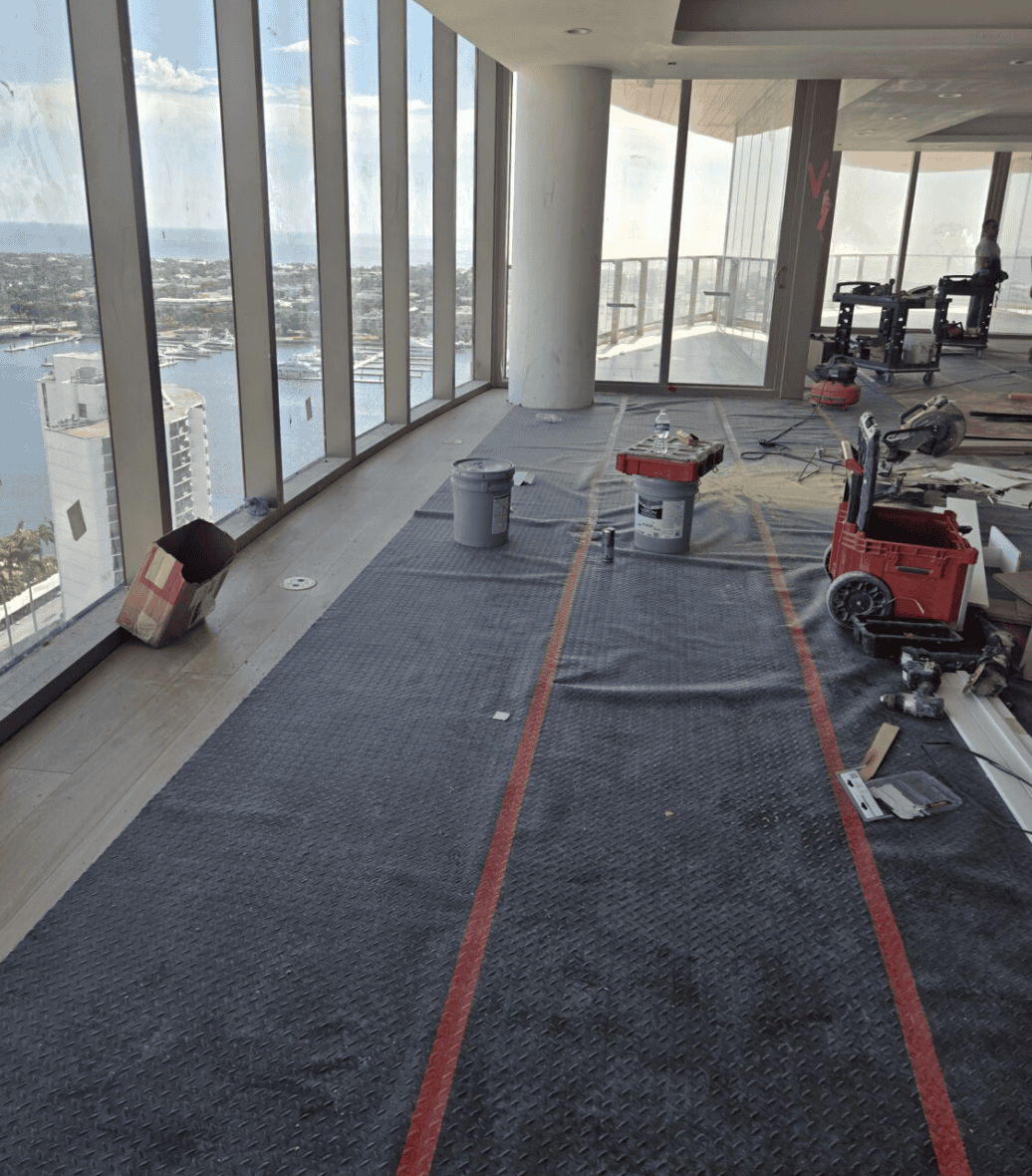

Unlike peel-and-stick films that tear easily under the strain of heavy tools or repeated foot traffic, reusable protectors like those from Surface Protection International are engineered for longevity, enduring multiple jobs without compromising performance. These advanced materials, such as FloorGuard and Diamond Plate Cover Guard, are lightweight, allowing contractors to roll them out swiftly across large areas, saving valuable setup time. Despite their portability, they’re robust enough to withstand the rigors of industrial environments, including the weight of heavy machinery, the scuffing of work boots, and the impact of dropped equipment. This durability translates to fewer replacements and less downtime, making them a cost-effective choice for busy job sites. Key perks include:

- Waterproofing: These protectors create an impermeable barrier that blocks rain, spilled liquids, and tracked-in mud during outdoor construction phases or in regions prone to wet weather. This feature is critical for preventing water damage to sensitive surfaces like hardwood or unfinished concrete, which can warp or stain if exposed to moisture over time.

- Non-Slip Grip: Safety is paramount on construction sites, and these reusable protectors feature textured surfaces designed to provide superior traction. This reduces the risk of slip-and-fall accidents, even in high-traffic areas where workers are carrying heavy loads or navigating wet conditions, ensuring compliance with OSHA safety standards and protecting your crew.

- Eco-Compliance: Reusable designs significantly reduce waste compared to disposable films, aligning with LEED (Leadership in Energy and Environmental Design) standards that prioritize sustainability. This eco-friendly approach appeals to clients who value green-building practices, giving contractors a competitive edge in environmentally conscious markets while contributing to a smaller carbon footprint.

Spotlight on Top Picks: FloorGuard and

Diamond Plate Cover Guard

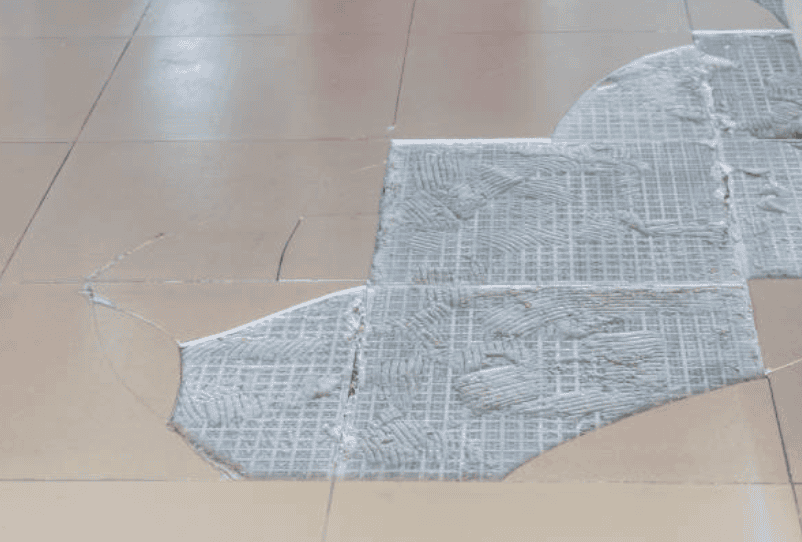

For construction floor protection that delivers reliability, FloorGuard from Surface Protection International stands out. This 10-mil polyethylene roll safeguards concrete, wood, tile, and counters from weather and debris. Its breathable design prevents moisture trapping, avoiding mold issues common in humid job sites. Reuse it up to 10 times with simple hosing—perfect for remodels or new builds.

Pair it with Cover Guard's Diamond Plate variant for high-traffic zones. This flame-retardant features a textured, non-skid surface mimicking diamond plating for superior traction. Ideal for vertical applications like walls or stairs, it resists tears from ladders and resists chemicals from paints or epoxies. At competitive pricing through Spycor, it's a contractor favorite for its versatility across residential and commercial projects.

Choosing the Right Construction Floor

Protection for Your Build

Selecting the ideal construction floor protection starts with a thorough assessment of your site’s unique demands. For wet environments, prioritize waterproof rolls like Surface Protection International’s FloorGuard Floor Protection, which offers robust defense against rain, spills, and mud, safeguarding delicate surfaces like hardwood or unfinished concrete.

In high-traffic areas, opt for Cover Guard’s Diamond Plate Cover Guard, engineered with a textured, non-slip surface to ensure worker safety and prevent slips under heavy loads or wet conditions. Measure your project area early— a 1,000 sq ft slab typically requires approximately three 36" x 100' rolls, factoring in overlaps for securely taped seams to create a seamless barrier.

To maximize effectiveness, consider site-specific factors such as surface type and environmental conditions. For instance, concrete curing in humid climates benefits from FloorGuard’s breathable properties, which prevent moisture trapping that could lead to mold or discoloration. For areas with heavy machinery or frequent ladder use, Diamond Plate Cover Guard’s tear-resistant, flame-retardant design provides peace of mind, meeting NFPA safety standards.

Pro tip: Always test a sample on-site to confirm compatibility with specialty finishes like vinyl composition tile (VCT) or epoxy coatings, as some adhesives or materials may interact differently. Proper planning and product selection ensure your construction floor protection delivers both durability and cost savings.

Investing in quality construction floor protection like FloorGuard and Diamond Plate Cover Guard isn’t just smart—it’s essential for bid-winning efficiency, client satisfaction, and maintaining a professional reputation. These reusable solutions save time, reduce waste, and protect your bottom line, making them indispensable for any contractor aiming to excel.

Explore Here to see the full range of reusable surface protectors and fortify your next project.

FAQ: Construction Floor Protection Essentials

What exactly is construction floor protection?

Reusable or temporary barriers like polyethylene sheets that shield floors from damage during building, renovation, or maintenance work.

How long does reusable floor protection last?

Products like FloorGuard withstand 5-10 uses, depending on site conditions, far outpacing disposables.

Is Diamond Plate Cover Guard safe for indoor use?

Yes, its flame-retardant rating meets NFPA standards, making it ideal for enclosed spaces with welding or electrical tasks.

Can I use construction floor protection on stairs?

Absolutely—Diamond Plate's grip texture prevents slips, and it's flexible for angled surfaces.

What's the ROI on reusable vs. disposable protection?

Reusable options recover costs after 2-3 jobs through reduced replacements and labor, per contractor surveys.