Posted by Spycor LLC on Nov 12th 2025

When hazardous materials like lead dust, crystalline silica, and mold spores are present, a vacuum is not just a cleaning tool—it is the single most critical piece of safety and regulatory compliance equipment you own. For professionals in abatement, restoration, and construction, using an "ordinary" vacuum to clean up these toxic particulates is not just inefficient; it is a catastrophic liability.

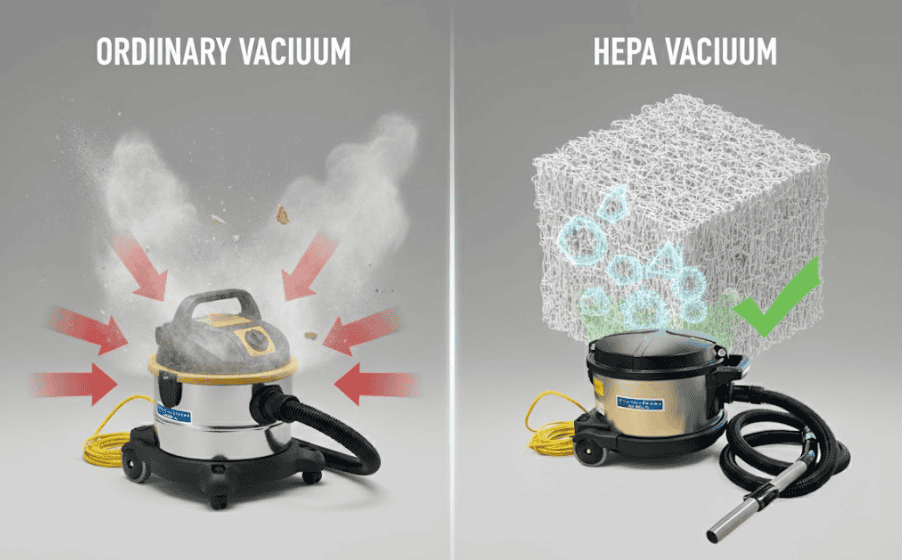

Ordinary vacuums, designed for general dirt, are utterly incapable of capturing and containing the ultra-fine particles that define these hazards.

The Compliance Imperative: Why Ordinary

Vacuums Guarantee Failure

The difference between successful containment and site contamination is the integrity of your filtration system. For high-risk materials, a vacuum must contain a certified HEPA filter and, crucially, possess a fully sealed body.

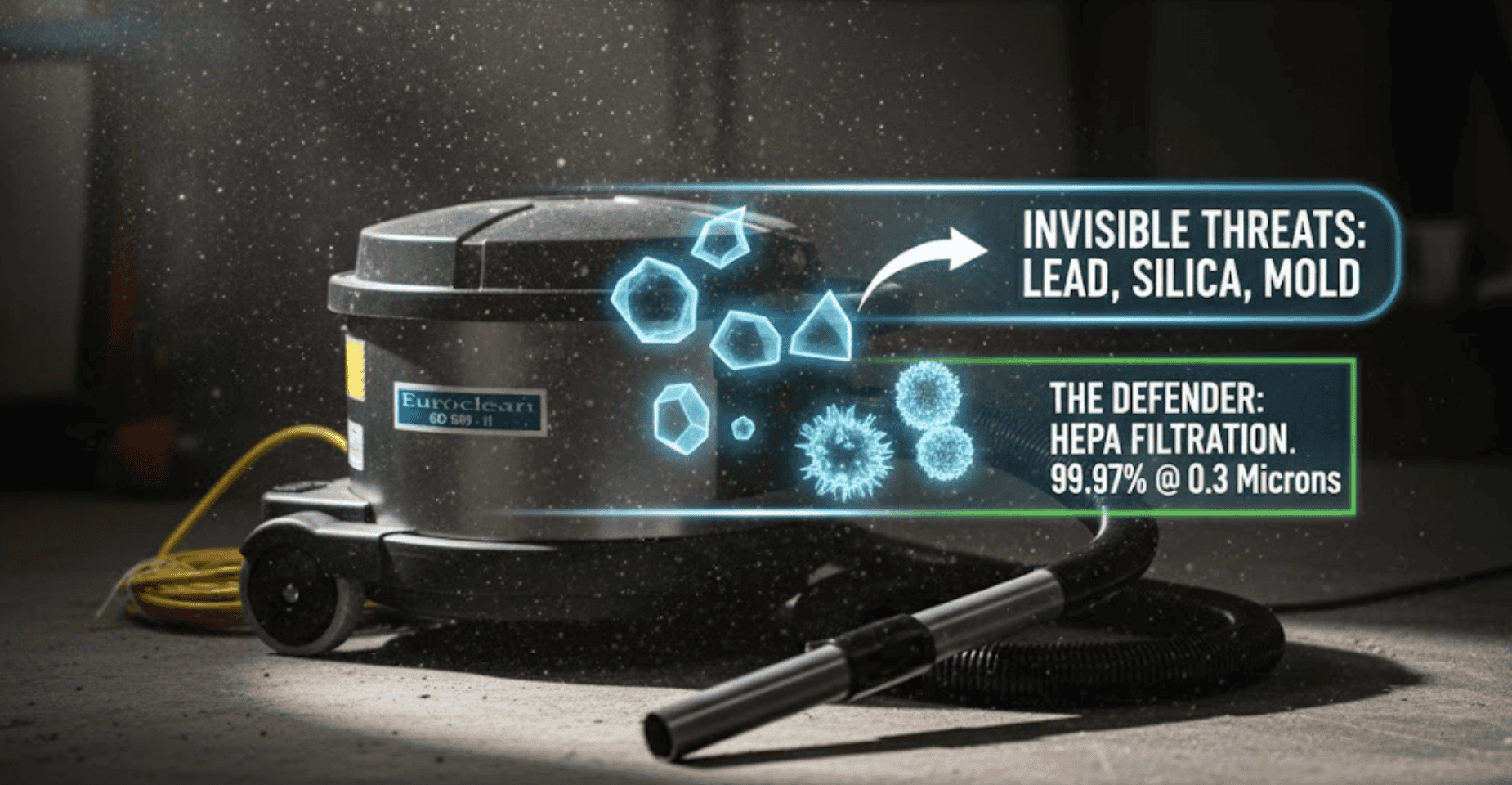

Crushing the Contaminants: The HEPA 99.97% Standard

A certified HEPA vacuum cleaner must be individually tested to capture 99.97% of airborne particles 0.3 microns in size.

- Lead Dust: When lead-based paint is disturbed, it creates extremely fine dust.

A large portion of this dust falls into or near the 0.3-micron range. An ordinary vacuum cannot capture this dust and will simply aerosolize it, creating a high-risk lead-in-air exposure that violates EPA Renovation, Repair, and Painting (RRP) standards. - Crystalline Silica: OSHA's Respirable Crystalline Silica Standard targets particles under 10 microns, with the greatest danger coming from particles less than 4 microns that penetrate deep into the lungs. Only a professional HEPA Vacuums can reliably capture this respirable silica dust, ensuring compliance with strict OSHA Table 1 guidelines.

- Mold Spores: While many mold spores are larger, the sub-micron fragments and mycotoxins they release are highly dangerous. The 0.3-micron efficiency of a HEPA filter ensures that these fine, allergenic, and toxic remnants are effectively contained, preventing spore re-settlement and cross-contamination during remediation.

The Sealed System: Eliminating the Leak Liability

Any vacuum can capture visible dirt. Only a professional hepa filter vacuum is engineered to eliminate air bypass.

Ordinary vacuums have weak seals around the motor housing, filter gaskets, and canister lids. When faced with the pressure generated by the vacuum motor, ultra-fine hazardous dust is forced through these tiny, unsealed gaps.

- Positive-Locking Gaskets: To ensure the filter seal is perfect.

- Sealed Motor Compartments: To prevent dust from passing through the motor and back out the exhaust.

- Multi-Stage Filtration: Utilizing a disposable containment bag and pre-filter to protect and extend the life of the certified HEPA cartridge.

Hazard-Specific Containment: Why HEPA

is Non-Negotiable

1. Lead Containment: Protecting Clients and Compliance

The RRP rule is clear: contractors must utilize cleaning methods that capture the maximum amount of lead dust. The most common enforcement failure is using a non-HEPA vacuum.

- The Danger: Lead poisoning is irreversible, particularly in children. It only takes a tiny amount of dust to contaminate an entire room.

- The Solution: A certified HEPA vacuum cleaner is the final, essential step in post-renovation cleanup.

It captures the invisible residue left after rough cleaning, ensuring clearance levels are met and preventing the homeowner from being exposed.

2. Silica Dust: Meeting the OSHA Standard Head-On

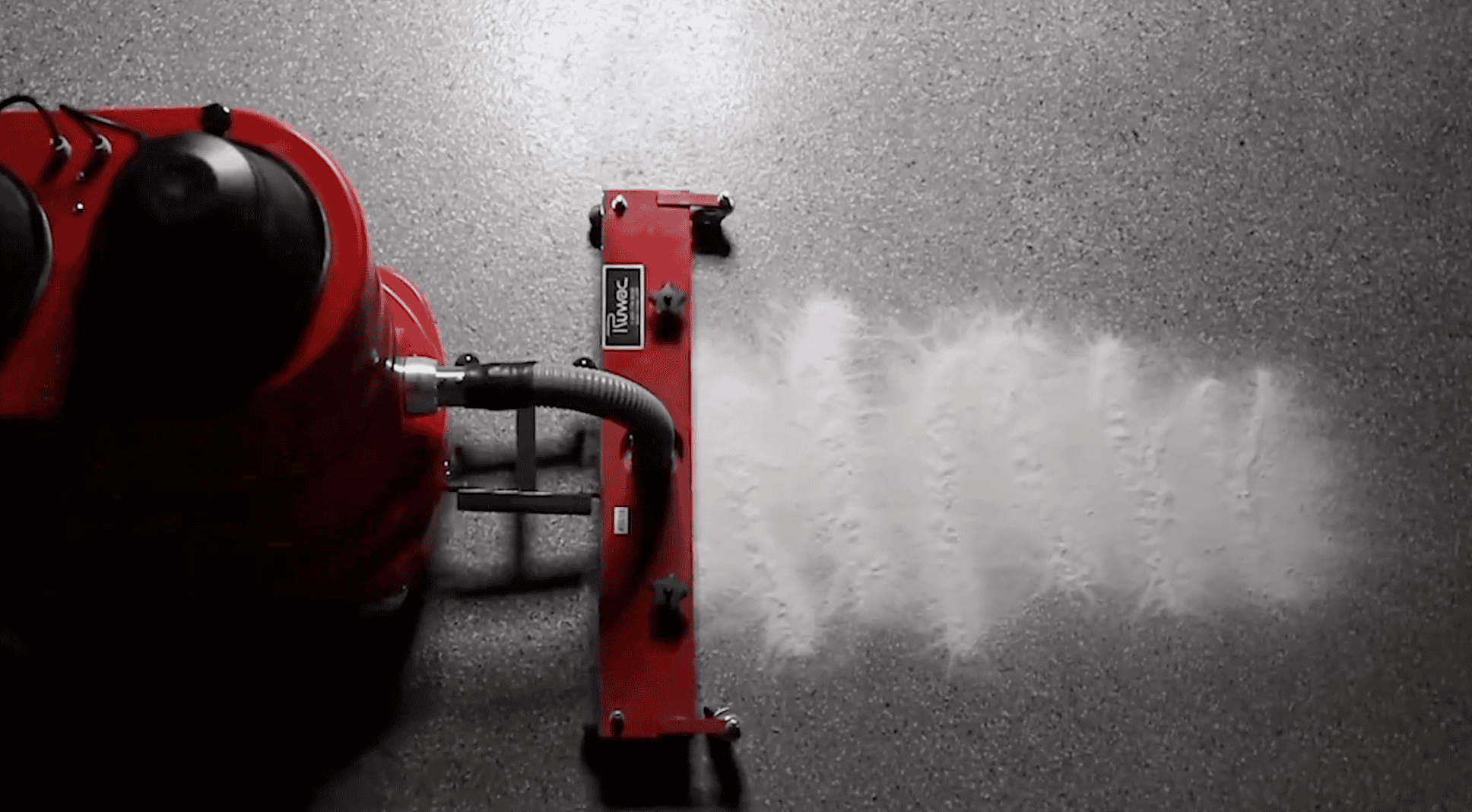

Silica dust exposure is one of the most serious health hazards on construction sites, leading to silicosis and lung cancer.

- The Danger: The extremely sharp, respirable silica particles remain airborne for extended periods.

Inhaling them causes permanent lung scarring - The Solution: Professional HEPA Vacuums are built with the capacity, power, and durability needed for continuous use with power tools (e.g., grinders and saws) and for post-work area cleanup. Investing in a high-quality, high-capacity hepa filter vacuum is the most effective engineering control to protect workers and avoid costly OSHA fines.

3. Mold Spore Remediation: Stopping the Spread

Mold remediation requires thorough removal without disturbing the spores and spreading them to unaffected areas.

- The Danger: Disturbing mold releases concentrated clouds of spores and mycotoxins.

A non-HEPA vacuum is the fastest way to contaminate an entire building through HVAC systems and air currents. - The Solution: In containment areas, a HEPA vacuum cleaner provides the only reliable method for cleaning contaminated surfaces (wood, drywall, concrete) and safely collecting and disposing of mold-infected debris. The sealed system ensures that once the spores are captured, they are never released back into the air.

The Cost of Failure vs. The Investment in

a Professional HEPA Vacuum

Choosing a professional HEPA Vacuums is a risk mitigation strategy. The initial cost is easily justified when weighed against the financial and human costs of using inadequate equipment.

- Fines and Stop Work Orders: Fines for violating EPA RRP or OSHA Silica standards can run into the tens of thousands of dollars, coupled with mandatory site shutdowns.

- Litigation and Health Claims: Worker or client health issues arising from contamination can lead to crippling lawsuits and insurance increases.

A professional hepa filter vacuum (such as the specialized models offered by Spycor Environmental) is a long-term investment in your business’s credibility, legal compliance, and operational safety.

Order Now the best HEPA Vacuums and filtration systems engineered for professional excellence and regulatory compliance in lead, silica, and mold containment.

FAQ Section: HEPA for Lead, Silica, and

Mold

Are all HEPA vacuums safe for lead dust cleanup?

Only those HEPA Vacuums that maintain the 99.97% efficiency rating and possess a fully sealed system are compliant and safe for lead dust cleanup under EPA RRP regulations. The entire machine must be certified, not just the filter.

Can a shop vac with a HEPA filter attachment contain crystalline silica dust?

No. A standard shop vac is not designed with the required sealed housing integrity. Attaching a HEPA filter alone does not create a true HEPA filter vacuum and will likely allow the fine, respirable silica dust to bypass the filter seal and motor compartment, failing OSHA compliance.

How does a HEPA vacuum prevent the spread of mold spores during remediation?

The HEPA vacuum cleaner prevents the spread of mold by capturing and containing the sub-micron spores and fragments within its sealed system.