Posted by Spycor LLC on Oct 7th 2025

The efficiency of a HEPA filter is often measured by its media, but the integrity of the filter frame is equally crucial. In commercial and especially cleanroom environments, the frame material determines resistance to environmental stress, the lifespan of the filter, and—most importantly—airtightness. Choosing between a traditional wood frame and a robust metal frame (aluminum or galvanized steel) is a choice between minimal cost and maximum performance. For facilities handling sensitive materials, volatile chemicals, or biological agents, the consequences of a filter failure due to a compromised frame far outweigh any marginal cost savings. A warped wood frame can rapidly turn a compliant cleanroom into a contamination zone, rendering expensive production processes useless and jeopardizing compliance certification. Therefore, discerning buyers must view the filter frame not as a mere casing, but as an essential engineering component that guarantees the seal required for achieving H13 and H14 filtration standards under real-world operational pressure.

Wood Frame HEPA Filters: The Cost-

Effective Option

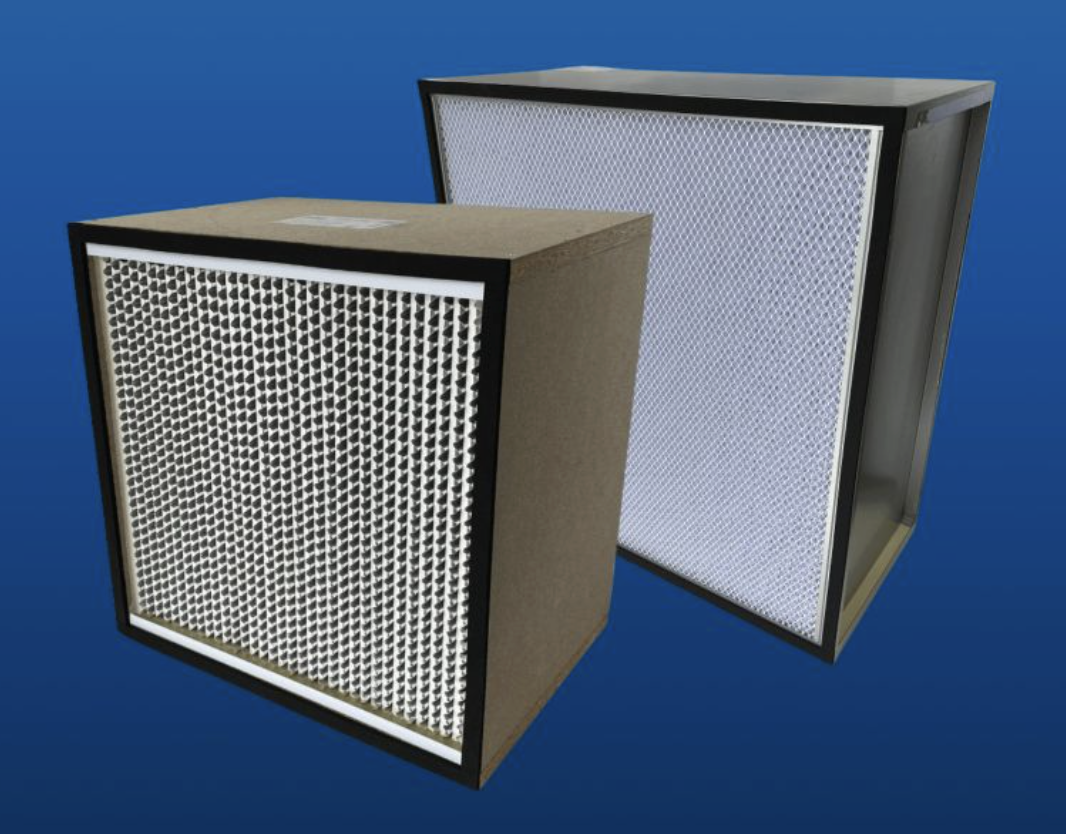

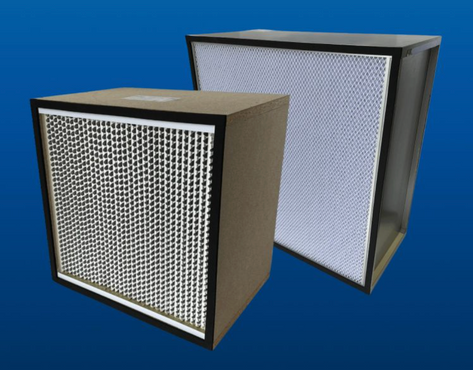

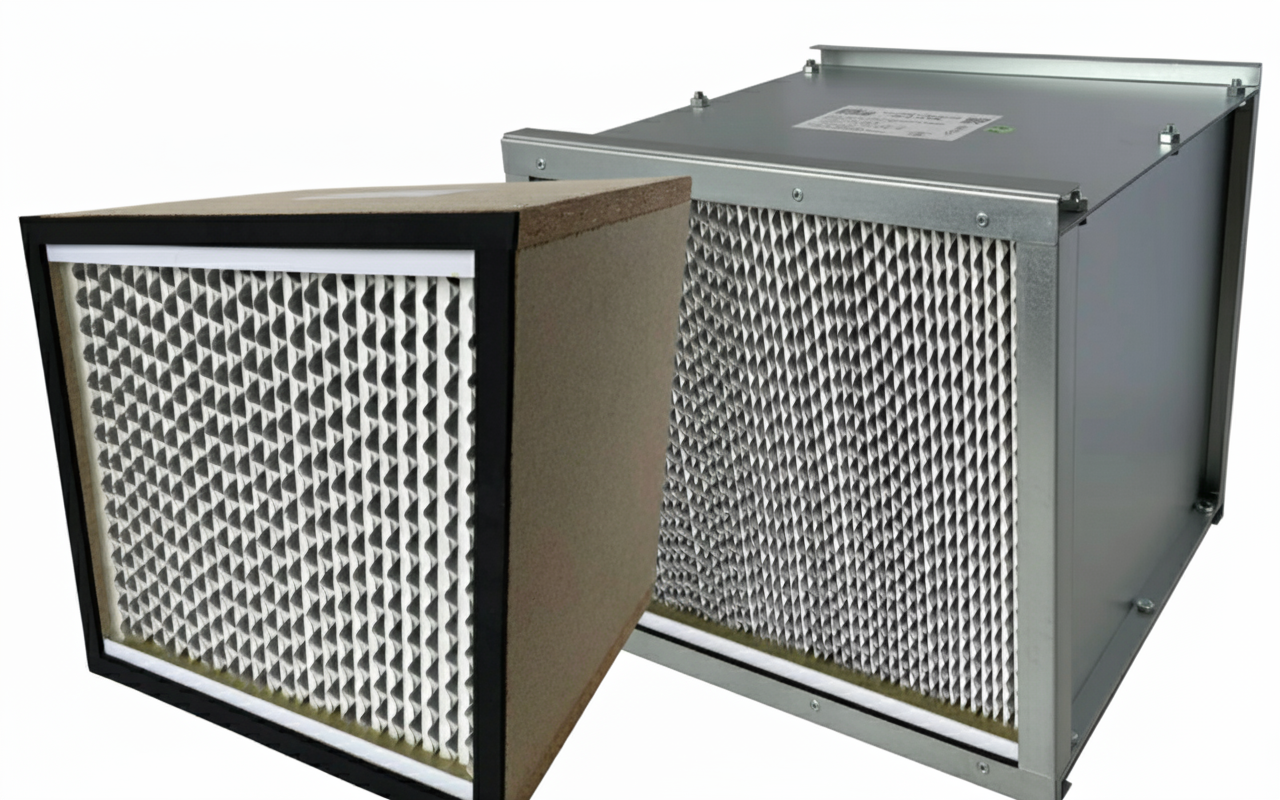

While often the cheaper initial option, wood frame HEPA filters maintain their relevance in certain environments. Their primary benefit lies in their low initial cost, making them highly economical for budget-conscious commercial HVAC systems, general industrial ventilation, or areas that do not require strict ISO cleanroom compliance. Additionally, wood frames are typically lighter than metal alternatives, simplifying installation and replacement. In applications where the air quality is ambient, humidity is tightly controlled, and the filtration system is not subject to high pressure surges, the wood frame offers an adequate, traditional solution that often features simpler end-of-life disposal compared to metal components.

The Limitations of Wood Frames

-

Moisture and Warping: Wood frames are highly susceptible to moisture absorption. In humid industrial settings, HVAC systems with cooling coils, or environments with decontamination wash-downs, the wood can warp, swell, or shrink. This compromises the critical seal between the filter frame and the housing, leading to catastrophic air bypass and immediate loss of filtration integrity.

-

Particulate Shedding: Over time, wood can shed fibers or particulate matter. In ISO-classified cleanrooms, where even micro-shedding can ruin product yield or compliance, wood frames pose an unacceptable contamination risk.

-

Pressure Limitations: Wood frames often lack the structural rigidity required for high-volume or high-static pressure HVAC systems, increasing the risk of frame failure or media damage.

The Superiority of Metal Frame HEPA

Filters

For virtually every modern commercial and industrial application, the metal frame HEPA filter is the superior, long-term choice. Whether constructed from galvanized steel for structural strength or aluminum for lighter weight and corrosion resistance, metal frames ensure maximum reliability.

-

Structural Integrity: Metal frames maintain their shape under the highest operational stress, preventing deformation that causes air leaks. They are essential for systems that experience frequent startups or high-velocity airflow.

-

Moisture and Chemical Resistance: Unlike wood, metal frames are impervious to moisture, making them ideal for all-weather AHUs, pharmaceutical manufacturing, and bio-containment areas requiring decontamination washes. This directly contributes to a longer, more predictable HEPA filter lifespan.

-

Optimal Sealing Capability: The smooth, uniform surface of a metal frame provides the perfect foundation for advanced sealing technologies, such as fluid gel seals or continuous poured polyurethane gaskets. These seals achieve airtight connections necessary for achieving H13 and H14 cleanroom standards.

Choosing for Cleanroom Compliance: The

Non-Shedding Mandate

For any facility aiming for ISO 7 (Class 10,000) or higher cleanliness levels, metal frame HEPA filters are non-negotiable.

-

Non-Shedding Materials: ISO 14644 standards prioritize materials that do not contribute to particulate contamination. Metal frames (especially anodized aluminum) are inherently non-shedding, unlike wood.

-

Leak Prevention: In a cleanroom, filtration is only as good as the seal. Metal frames are robust enough to withstand the pressure of knife-edge or gel seal housing designs, ensuring zero air bypass—the single greatest threat to cleanroom certification.

Investing in a durable metal frame HEPA filter ensures regulatory compliance and protects high-value processes from contamination.

Stop risking contamination with outdated wood frames. Upgrade to maximum integrity filtration solutions.

Click Here to choose the best HEPA Filters and H13/H14 Rated Products designed for the strict demands of Commercial and Cleanroom.